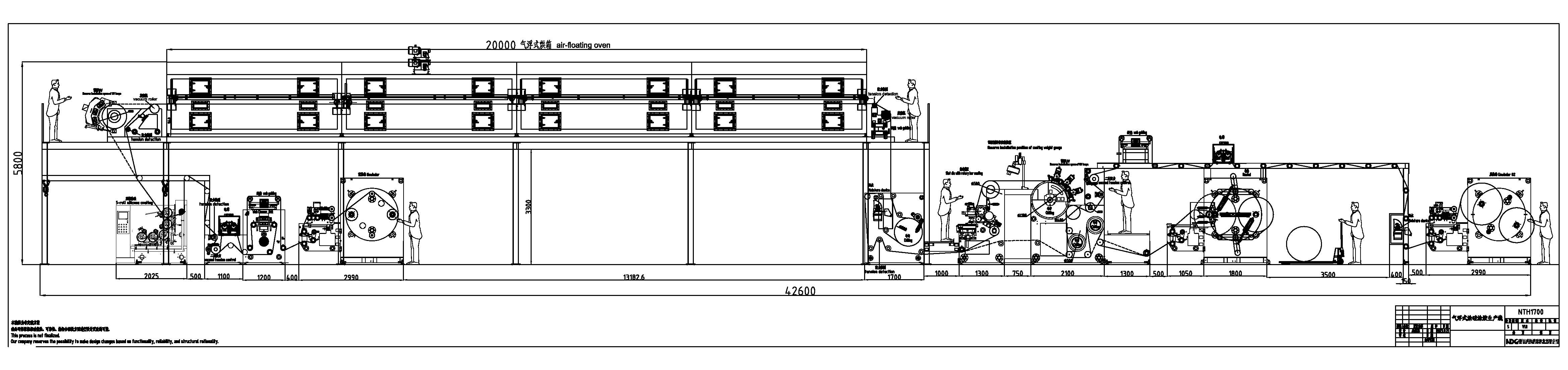

NDC has developed an integrated silicone coating and glue coating for the precise application to a wide range of Linerless and pressure-sensitive labels as well as tape with online silicone coating. The integrated coating line includes with many different components, from unwind to rewind producing variety items for the client's product line up

Technology facts

1.Line speed: 300m/min

2.Material width: 1600mm

3.Real diameter: 1200mm

4.Unwinder: automatic turret unwinding

5.Rewinder: automatic turret rewinding

Silicone coating technology

1.Coating method:5-roller silicone coating (Optionally with 3 rollers )

The 5-roller system meticulously controls the application of silicone and the coat weight. The anilox roll applies the silicone from the buffer to the coating roll with exactly the right thickness. The coating roll then applies the silicone to the substrate. Each variable speed roll is independently driven delivering incredible precision. It also offers the ability to apply low silicone coat weights, making it a great unit to tap into the growing market for Linerless direct thermal labels

2.Silicone type:UV silicone coating; Silicone-free coating

3.Application:suitable for high speed single side silicone coated release liner (glassine, SCK, CCK, PCK, etc.) and film liner(BOPP, PE, PET) production

Coating technology

1.Coating method:slot die coating with rotary bar

It takes 90 days with 11 processing steps to finish a set of coating die to achieve high coating quality.

2,Application:Hot melt glue; UV glue; Water-based

Drying technology

1.Air flotation dryer with high efficient to ensure proper silicone cure at high speed

2.4 sections dryers, length 5m for each section

3.Humidity detection and control of recirculation air

4.Equipped with tension detection and vacuum rollers in the front and rear section of dryer module to control tension during the process.

5.High performance convection oven for all coating compounds

Components

Corona treatment (optional)

Reserve installation space for UV-lamp system

Web guiding

Tension control

Online glue thickness gauge (optional)

Spray plate moisture

Steam moisture

Web cleaner

The system solution that NDC engineered featured a number of process improvements and designs that helped the new line see an increase in speed and cost-effectiveness. We have the knowledge and experience to make the project a success. Anymore information needed, please contact us by email: info@ndccn.com

Post time: Mar-05-2024